Item No :

ZDkmj-IIPayment :

T/TCountry Origin :

ChinaPort of Loading :

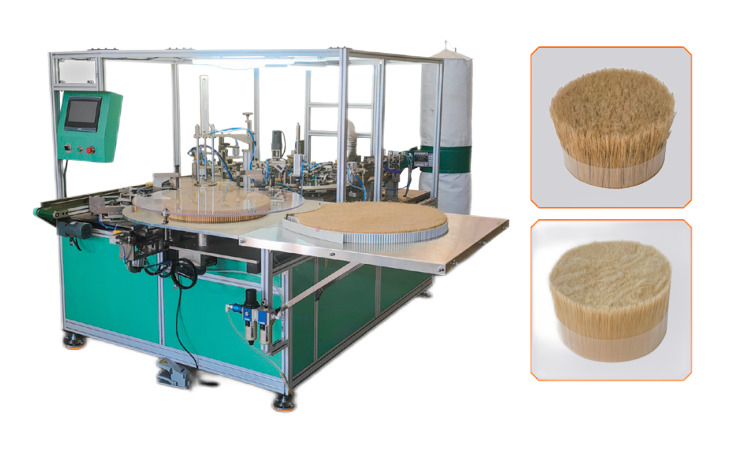

XiamenAutomatic Bristle & Filament Binding Machine

The Automatic Bristle & Filament Binding Machine is a high-performance solution specially designed for the efficient binding of bristles and filaments in brush production. It integrates automatic feeding, positioning, cutting, and binding processes into a single compact system, ensuring superior precision, stability, and speed.

Equipped with an advanced PLC control system and servo-driven motors, this machine delivers consistent tension and uniform binding quality, making it ideal for producing various types of brushes — including paint brushes, cleaning brushes, industrial brushes, and cosmetic brushes. The intelligent operation interface enables quick parameter settings, automatic fault detection, and smooth production management with minimal human intervention.

Built with durable components and precision mechanisms, the Automatic Bristle & Filament Binding Machine greatly improves production efficiency, reduces labor costs, and ensures consistent quality in every bundle.

- Product Detail

Applicable diameter of raw material feeder: ≤600mm

Outer diameter of finished: 74-75mm

Applicable raw material: from 51mm to 120mm in length for natural bristles, synthetic filament or mixture of bristle & filament

- Specifications

|

Machine dimensions |

2.73m x 2.6m x 1.9m |

|

Rated power supply |

AC 220V, 50Hz |

|

Rated power |

7kw |

|

Air consumption |

about 0.6m³ per minute; |

|

Applicable diameter of raw material feeder |

≤600mm |

|

Outer diameter of finished |

74-75mm |

|

Applicable raw material |

from 51mm to 120mm in length for natural bristles, synthetic filament or mixture of bristle & filament |

|

Production capacity |

100-120pcs per hour |

|

Operator required |

2 |

- Why Choose Us:

- Transportation & After-sales Service

All the machines shall be packed in export plywood crates.

Engineers are available to provide service aboard.

Training &Technical instructing lessons shall be provided during installation.

Video instruction installation is also available if customers have professional technical engineers.

A one-year warranty is provided to the customer.

-F&Q

Q1: What is the production capacity of the machine?

A1: The production speed can reach 100-120 pcs/hour. Ensuring high output with stable performance.

Q2: How difficult is it to operate and maintain this machine?

A2: The system adopts an intelligent touch screen control panel and automatic alarm protection. It’s easy to operate even for new workers, and daily maintenance mainly includes cleaning and regular lubrication.

Q3: What kind of after-sales service do you provide?

A3: We provide remote technical support, video training, and on-site installation guidance (if required). Spare parts and quick-response service ensure long-term reliability.

leave a message

Scan to wechat :

Scan to Whatsapp :