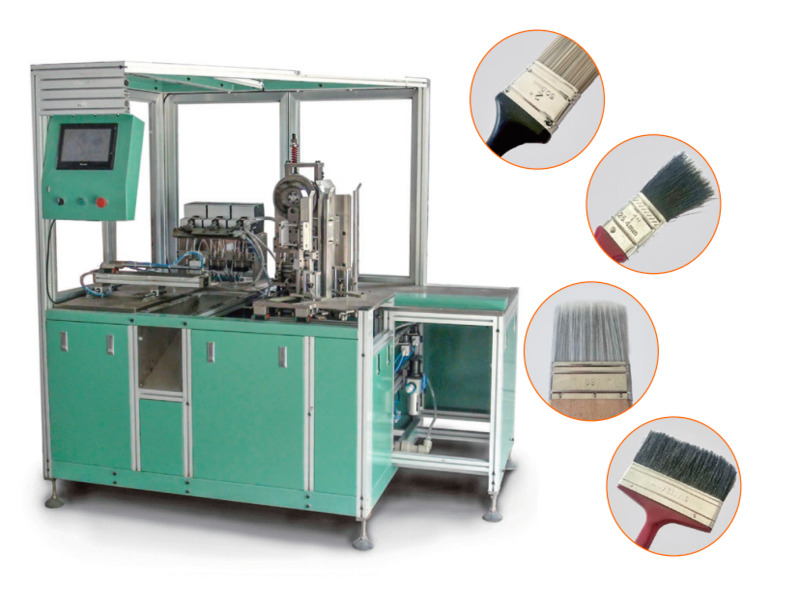

Automatic Paint Brush Handle Inserting and Nailing Machine (0.5''-6'')

Item No :

TBddj-IVPayment :

T/TCountry Origin :

ChinaPort of Loading :

XiamenAutomatic Paint Brush Handle Inserting and Nailing Machine

Hengyu Automatic Set Handle & Nailing Machine is a fully automated system engineered for the high-precision and high-efficiency assembly of paintbrushes. It specializes in seamlessly setting the metal ferrule onto a pre-fitted handle and automatically driving and clinching the fasteners to secure the assembly permanently.

This machine is widely used in paint brush factories, brush assembly lines, and automation workshops seeking to enhance efficiency, reduce labor costs, and achieve stable product quality. Built with durable components and precision engineering, it guarantees long service life and low maintenance requirements.

- Product Detail & Features

Applicable sizes: from 0.5" to 6" for flat brushes in width

Applicable handle material: from 120mm to 270mm for plastic or wooden handle in length

Fully Automated Operation: It automatically positions the handle, drives and sets nails in a single, seamless cycle.

High Speed & Precision: Ensures consistent and accurate nailing, significantly increasing production output and product quality.

Enhanced Safety: The automated process minimizes operator contact with moving parts, creating a safer working environment.

Robust & Reliable: Built for continuous operation in industrial settings, ensuring long-term durability and minimal downtime.

- Specifications

|

Machine dimensions |

1.6mx1.3mx2.1m |

|

Rated power supply |

AC 220V, 50Hz |

|

Rated power |

1.0kw |

|

Air consumption |

about 0.6m³ per minute; |

|

Applicable sizes |

from 0.5" to 6" for flat brushes in width |

|

Applicable handle material |

from 120mm to 270mm for plastic or wooden handle in length |

|

Production capacity |

1000-1200pcs per hour |

|

Operator required |

1 |

- Why Choose Us:

- Transportation & After-sales Service

- F&Q

Q1: What is the production capacity of the machine?

A1: The production speed can reach 1200 pcs/hour. Ensuring high output with stable performance.

Q2: How difficult is it to operate and maintain this machine?

A2: The system adopts an intelligent touch screen control panel and automatic alarm protection. It’s easy to operate even for new workers, and daily maintenance mainly includes cleaning and regular lubrication.

Q3: What kind of after-sales service do you provide?

A3: We provide remote technical support, video training, and on-site installation guidance (if required). Spare parts and quick-response service ensure long-term reliability.

leave a message

Scan to wechat :

Scan to Whatsapp :