Item No :

ZDzmj-IV-LPayment :

T/TCountry Origin :

ChinaPort of Loading :

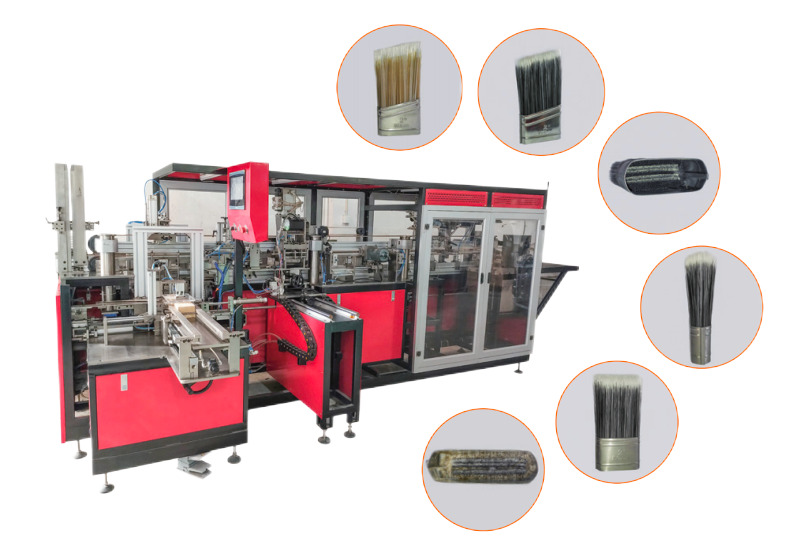

XiamenAutomatic Paint Brush Head Making Machine

The Hengyu Automatic Paint Brush Head Making Machine is an advanced production solution designed for high-efficiency paint brush head manufacturing. This machine integrates automatic feeding, trimming, shaping, and clamping processes into one streamlined operation, significantly improving production accuracy and output capacity.

Equipped with a precise control system and durable components, it ensures consistent quality and stable performance even under continuous operation. Its intelligent interface allows easy parameter adjustment and real-time monitoring, reducing labor costs and minimizing manual errors

- Product Detail & Features

Applicable ferrule sizes: from 1" to 5" in width for flat ferrule and from 1" to 4" in width angled ferrule, 6mm to 30mm in thickness

Applicable filling hair material: from 44mm to 155mm in length for natural bristles, synthetic filament or mixture of bristle & filament

- Specifications

| Machine dimensions | 4.0m x 1.7m x 1.7m |

| Rated power supply | AC 220V, 50Hz |

| Rated power | 3.5kw |

| Air consumption | about 0.6m³ per minute; |

| Applicable ferrule sizes | from 1" to 5" in width for flat ferrule and 1'' to 4'' in width for angled ferrule, 6mm to 30mm in thickness |

| Applicable filling hair material | from 44mm to 155mm in length for natural bristles, synthetic filament or mixture of bristle & filament |

| Production capacity | 1000-1200pcs per hour |

| Operator required | 2 |

- Why Choose Us:

- Transportation & After-sales Service

- F&Q

Q1: What materials can this paint brush head making machine process?

A1: The machine is compatible with a wide range of materials, including synthetic fibers (PP, PET, PBT) and natural bristles. It allows flexible adjustment for different brush head types and sizes.

Q2: What is the production capacity of the machine?

A2: Depending on brush size and filament type, the production speed can reach 1,200–1,800 pcs/hour. The fully automatic feeding and shaping system ensures high output with stable performance.

Q3: How difficult is it to operate and maintain this machine?

A3: The system adopts an intelligent touch screen control panel and automatic alarm protection. It’s easy to operate even for new workers, and daily maintenance mainly includes cleaning and regular lubrication.

Q4: Can the machine be customized for different brush types?

A4: Yes. We offer customized molds and configurations for flat brushes, round brushes, and industrial brushes, allowing clients to produce various brush shapes efficiently.

Q5: What kind of after-sales service do you provide?

A5: We provide remote technical support, video training, and on-site installation guidance (if required). Spare parts and quick-response service ensure long-term reliability.

Q6: What is the working principle of the Fully Automatic Paint Brush Head Making Machine, and how does it work?

A6: The machine operates through a fully automated process that ensures precise and efficient brush head production. It begins with automatic ferrule feeding, followed by hair material feeding from the hopper. The bristles are automatically inserted into the ferrule, and plastic wedges are placed to secure the material tightly.

Once inserted, the vibration system aligns the bristles evenly, ensuring a smooth and uniform brush surface. The machine then adjusts the hair height to the required level, performs precision trimming, and combs the brush head to achieve a clean, consistent finish. Finally, the completed brush heads are automatically transferred to the next production step.

This seamless workflow minimizes manual labor, improves accuracy, and ensures consistent product quality across every cycle.

leave a message

Scan to wechat :

Scan to Whatsapp :