Item No :

turnkey brush making systemPayment :

T/TCountry Origin :

ChinaPort of Loading :

XiamenTurnkey Paint Brush Production System

Turnkey Paint Brush Production System is a fully automated and high-efficiency system designed to streamline the entire brush manufacturing process — from material feeding, tufting, trimming, to final assembly. Equipped with advanced PLC control and servo-driven technology, this intelligent production line ensures exceptional accuracy, consistent performance, and reduced labor costs.

This turnkey system integrates multiple functional modules within one complete line, allowing manufacturers to produce paint brushes with minimal manual intervention. The modular design provides flexibility for customization according to different brush sizes, materials, and production requirements.

- Product Detail

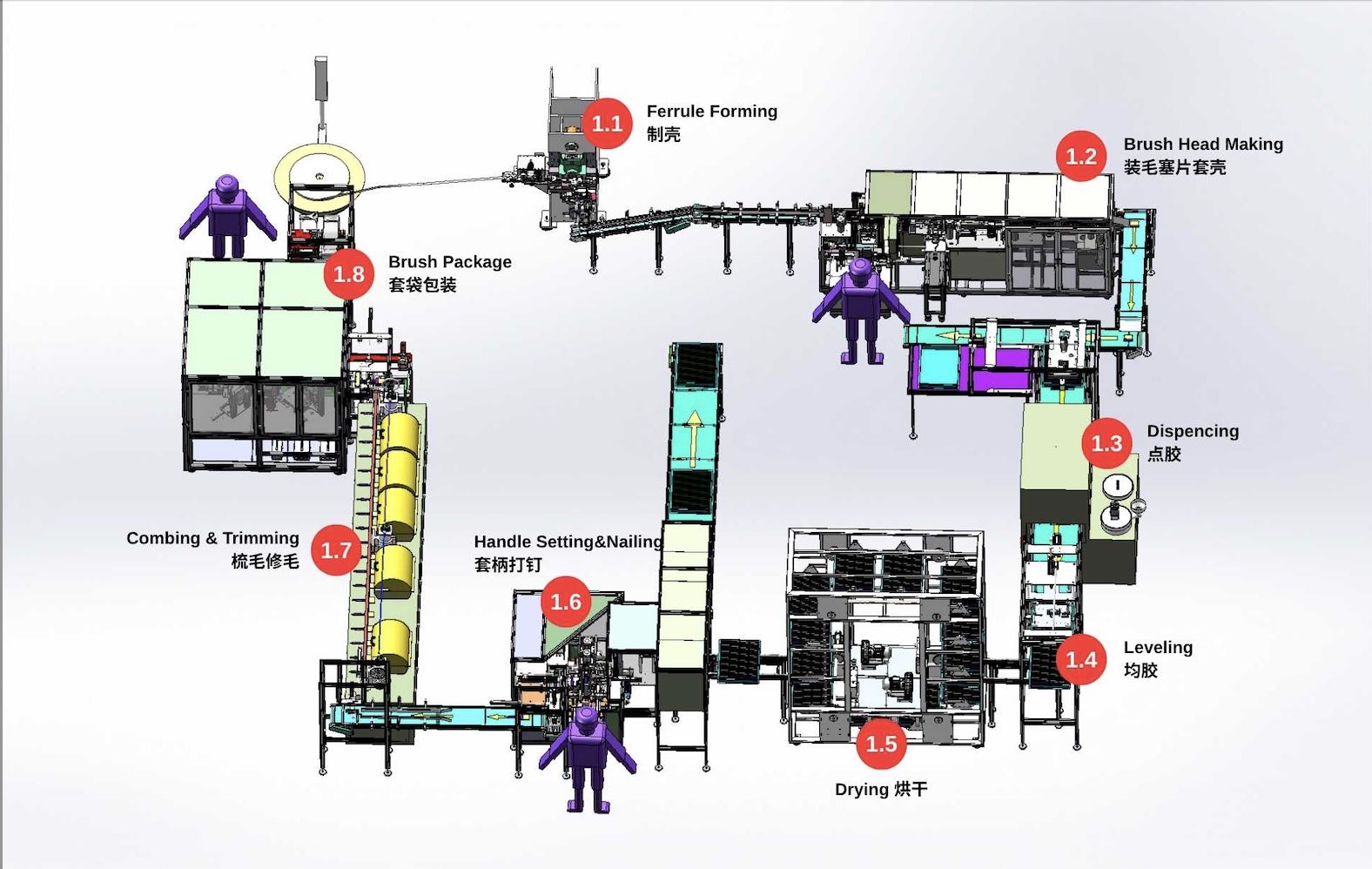

Zhangzhou Hengyu's integrated brush production line solution incorporates equipment for every step of the manufacturing process, from brush ferrule molding to final packaging. The system achieves highly automated operations while minimizing manual intervention, effectively reducing clients' labor and administrative costs. This ensures every finished paint brush maintains consistently reliable high-quality standards.

- Specifications

|

Dimensions |

12.7m x 11.1m x 3.2m |

|

Outer diameter of finished |

from 2" to 5" in width for flat ferrule, 6mm to 30mm in thickness |

|

Applicable raw material |

from 44mm to 155mm in length for natural bristles, synthetic filament or mixture of bristle & filament |

|

Production capacity |

1200pcs per hour |

|

Operator required |

3 |

- Why Choose Us:

- Transportation & After-sales Service

All the machines shall be packed in export plywood crates.

Engineers are available to provide service aboard.

Training &Technical instructing lessons shall be provided during installation.

Video instruction installation is also available if customers have professional technical engineers.

A one-year warranty is provided to the customer.

-F&Q

Q1: What is the production capacity of the machine?

A1: The production speed can reach 1200pcs/hour. Ensuring high output with stable performance.

Q2: How difficult is it to operate and maintain this machine?

A2: The system adopts an intelligent touch screen control panel and automatic alarm protection. It’s easy to operate even for new workers, and daily maintenance mainly includes cleaning and regular lubrication.

Q3: What kind of after-sales service do you provide?

A3: We provide remote technical support, video training, and on-site installation guidance (if required). Spare parts and quick-response service ensure long-term reliability.

leave a message

Scan to wechat :

Scan to Whatsapp :